Filter bags

Filter bags are often an important part of a

process. The filter may be essential in protecting the environment or in

collection of a product. Thus, the filter’s specific function is decisive for

an efficient process.

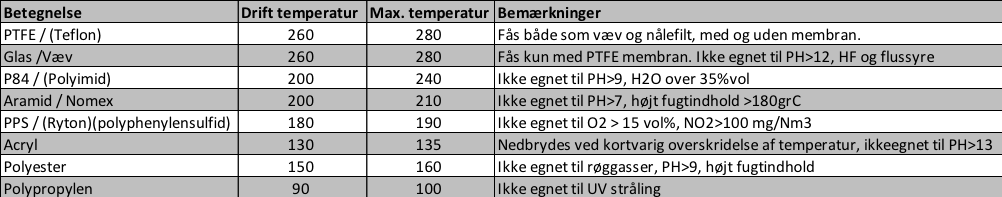

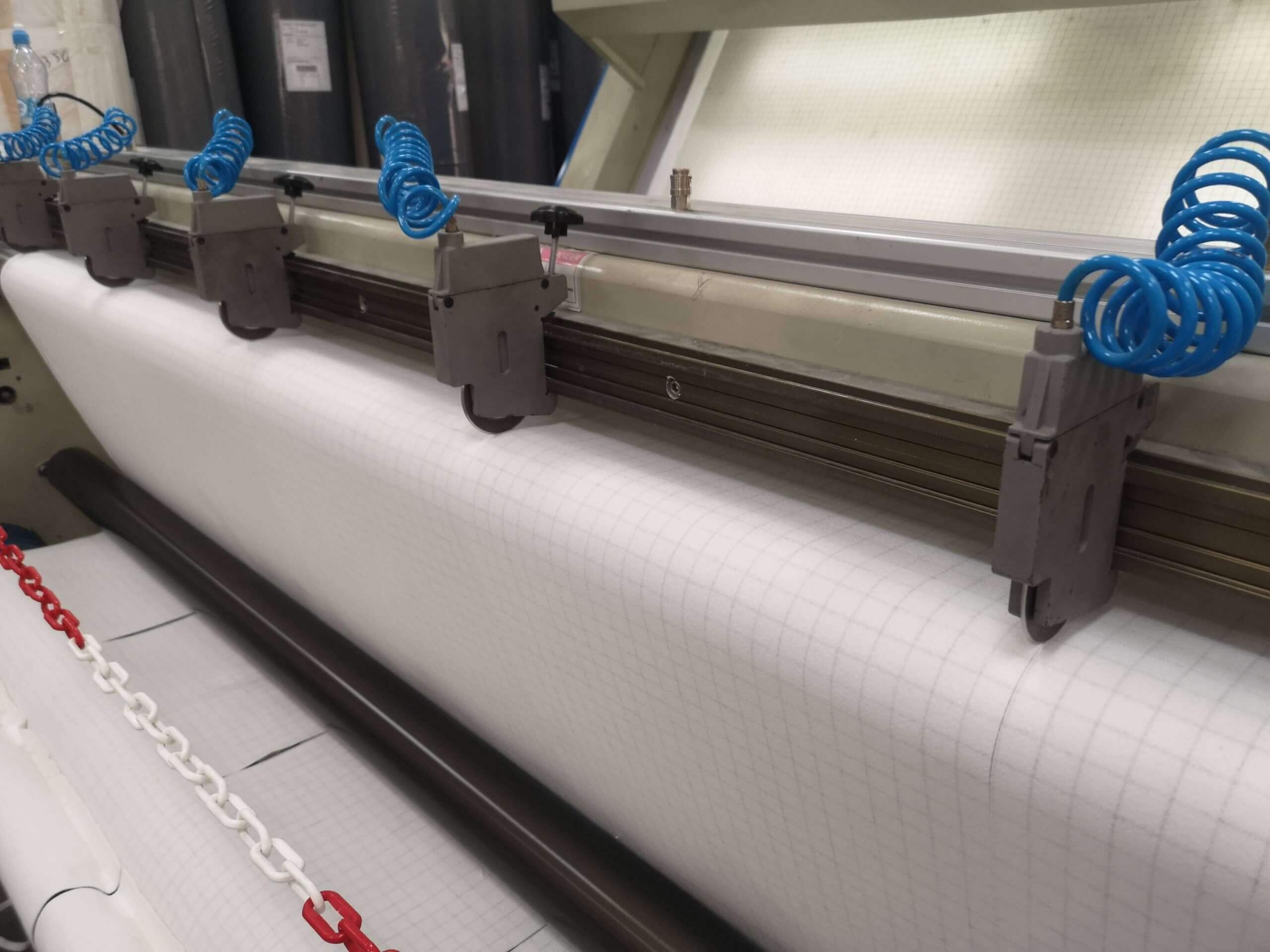

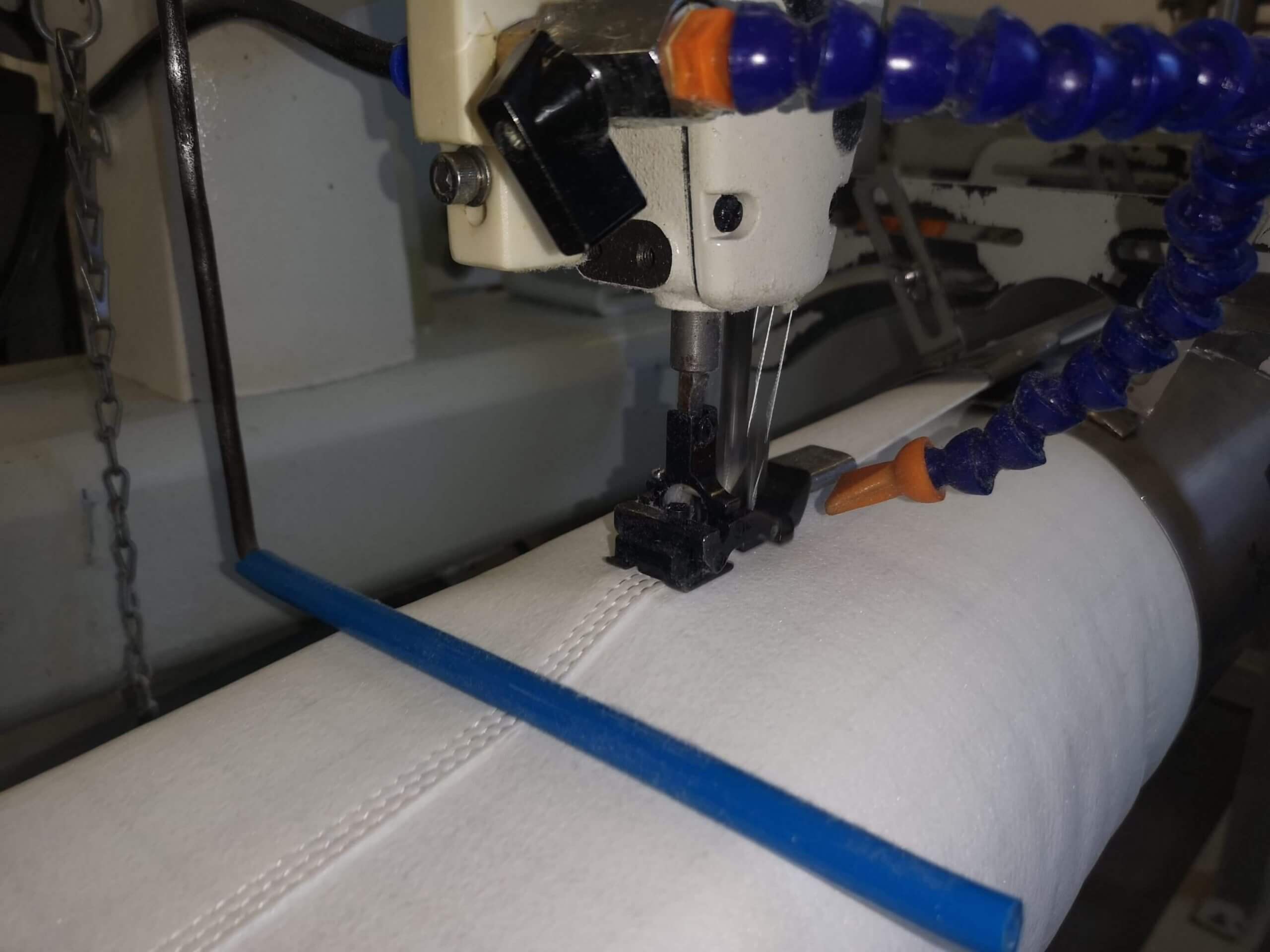

At Safematic, filter bags are manufactured

according to the process conditions where the bags will be used.

Requirements on emissions, temperature

conditions, dust load and dust composition are just some of the factors that

determine the materials used to produce a filter bag.

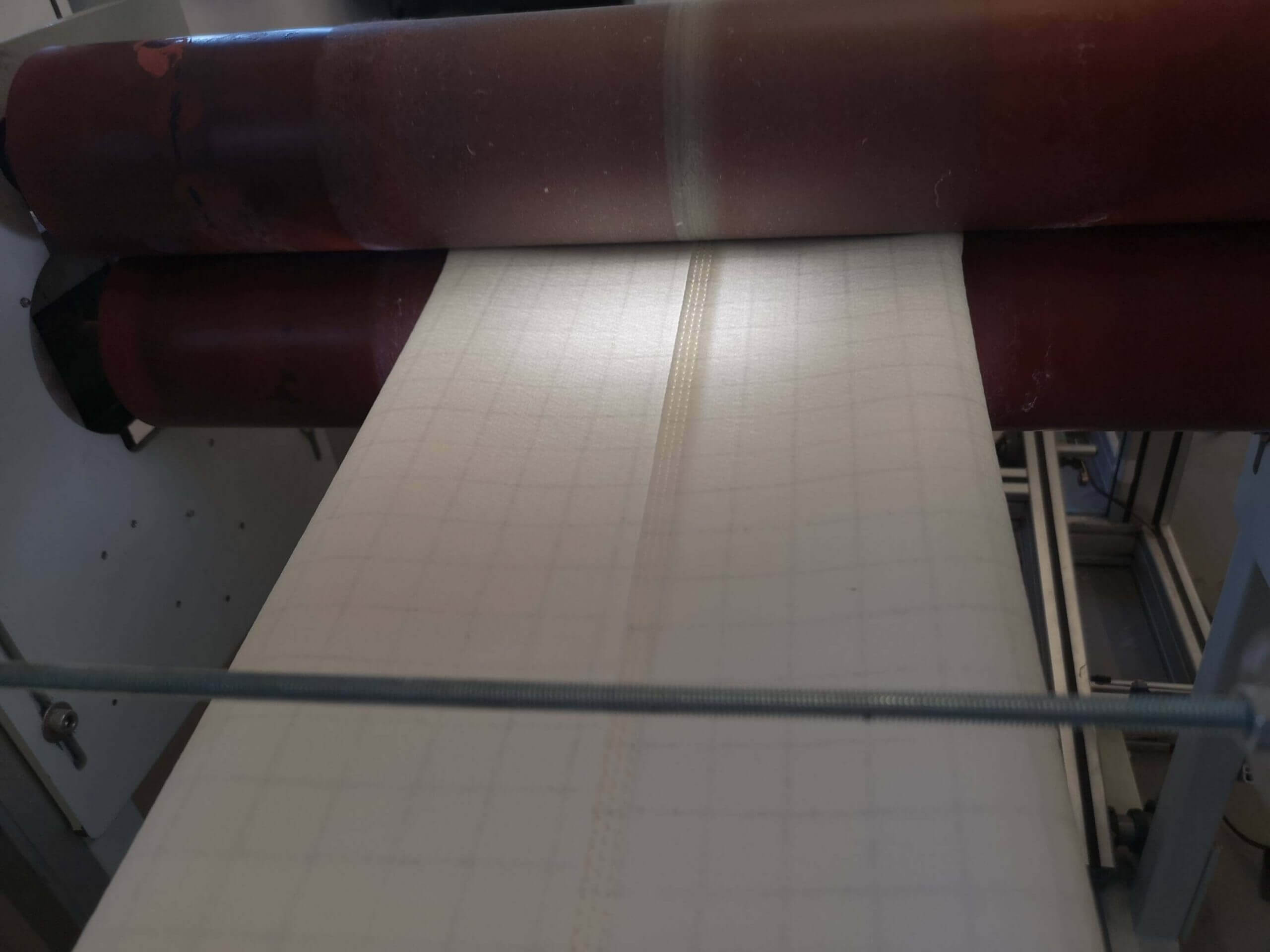

Filter materials are available in a wide

variety. The materials table at the bottom of this page describes the various

main material groups. Temperature is the first parameter to be considered when

selecting material. Other factors, such as the content of gases and

pH value, help identify the right material for the task.

Once the base material is selected, the surface

must be selected. Emission limits and the nature of the dust to be filtered

play an important role here. Supplier experience is an important part of

choosing the right solution. With Safematic, selection always takes place as a

dialogue between supplier and customer.

Contact Safematic and get help choosing the right filter material.

Filter bags for the food and pharmaceutical industries

Filter bags for food production must be made of materials that comply with Regulation (EC) No. 1935/2004 of 27 October 2004 on materials and articles intended to come into contact with food.

Similarly, during the manufacture of filter bags for food production, work must be carried out in accordance with Regulation (EC) No. 2023/2006 of 22 December 2006 on good manufacturing practice for materials and articles intended for contact with food.

FILTER BAGS FOR FOOD PRODUCTION

- Manufactured from materials complying with EN 1935/2004

- Manufactured according to EN 2023/2006

- Production areas and machines are cleaned before production starts

- Filter bags are protected against contamination

- Checked and packed individually

GOOD MANUFACTURING PRACTICE

- No edges with loose fibres

- Individual cleaning and inspection

- Filter bags are individually packed in a sealed bag

- Declaration of conformity included with the filter bags

- Traceability of filter bags

- Labelling of deliveries

Safematic has extensive experience in supplying filter bags for food production. Food safety is very important, and therefore Safematic has worked systematically to ensure quality from the start.

Food safety primarily involves prevention of the transfer of chemical substances from the filter media to food. Therefore, all materials used for food production must undergo a migration test. Upon delivery to the buyer, a document is including to certify that the filter-bag material complies with the requirements of EN 1935/2004.

Food production filter bags must be manufactured so that fibres or other materials cannot spread from the filter bags to the food product. Finally, filter bags and materials must be traceable. At Safematic, we maintain strict control of these factors. We are ready to help you solve filter challenges

Product versions

|

|

|

|---|---|

| Download |